testing concrete psi|concrete psi ratings chart : supplier Testing Concrete PSI. Accurate testing of concrete PSI is vital to ensure quality control and structural integrity. Various methods are used for testing PSI, including destructive and non-destructive techniques such as compression . São Carlos - SP - Brasil. (16) 3307-6006. Você pode acessar a programação através do smartphone usando o Aplicativo São Carlos Oficial. INGRESSOS. 2D. 3D. INTEIRA. R$24,00. R$24,00.

{plog:ftitle_list}

Conta Online - MEU TIM - Login

What They Mean and Next Steps and Evaluating Test Results and Troubleshooting Low Compressive Strength. References: ACI 301-20; ACI 311.6-18; ACI 318-19; ACI 214R-11; . Here’s a basic step-by-step guide to testing concrete psi chart and compressive strength. Prepare the sample: Take a concrete sample from freshly-poured concrete. Pour the sample into your cube or cylinder mold. Use a .

Testing Concrete PSI. Accurate testing of concrete PSI is vital to ensure quality control and structural integrity. Various methods are used for testing PSI, including destructive and non-destructive techniques such as compression .Sections 26.5.3.2 and 26.12.1.1 of ACI 318-19, ACI 301-20 “Specifications for Concrete Construction”, and ACI 311.6-18 “Specification for Testing Ready Mixed Concrete” require concrete strength tests for acceptance to be the average of at least two 6 x 12 in. (150 x 300 mm) cylinders or at least three 4 x 8 in. (100 x 200 mm) cylinders. Forget about the strength of the concrete that is there. Your eally do not know how consistant it is and how uniform the thickness is. You will need a separate foundation for a lift unless you can spread the load over huge area without any part of the load being concentrated (virtually an impossible gamble). Just to add up, Concrete suppliers and contractors need accurate, on-site testing of concrete or mortar strength so they can make the adjustments necessary to satisfy their customers and build high-quality structures. But transporting a full-sized laboratory to a job site is not always practical or convenient. This publication describes the .

The ideal concrete psi for a given project depends on various factors, but the bare minimum for any project usually starts around 2,500 to 3,000 psi. . The split tensile strength of concrete is determined using a split tensile test on concrete cylinders. The test should be performed according to the ASTM C496 standard. Flexural strength of .

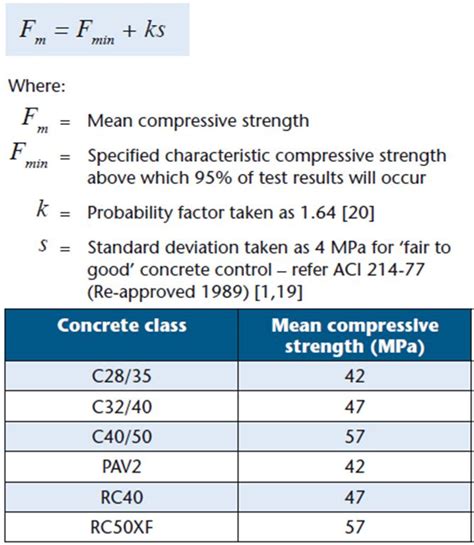

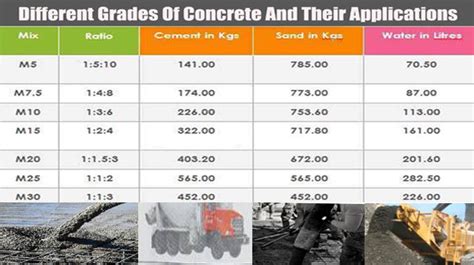

The compressive strength of the concrete cube test provides an idea about all the characteristics of concrete. By this single test one judge that whether Concreting has been done properly or not. . (2200 psi) to 30 MPa (4400 psi) and higher in commercial and industrial structures. Compressive strength of concrete depends on many factors such .

Budget: Higher PSI concrete typically costs more than lower PSI mixes, so weigh the benefits of increased strength against budget constraints. Conclusion: Choosing the right PSI in concrete is crucial for ensuring the durability, safety, and longevity of your project. By understanding the different PSI ratings and considering factors such as . The higher the PSI value, the stronger the mixture. Various concrete testing methods are used to determine strength, including compressive strength tests, tensile strength tests, and flexural strength tests. Conducting these tests is key to assessing concrete performance and validating its load-bearing capacity. . Builders use 5,000 PSI .Concrete PSI is a measure of the compressive strength of concrete. It indicates the amount of force, in pounds per square inch, that concrete can withstand before it fails or breaks. The higher the PSI, the stronger the concrete. Different projects require varying levels of PSI to ensure the structural integrity and longevity of the concrete.

In depth overview of testing fresh concrete. Learn about concrete testing procudes including concrete slump tests. Find out what testing equipment is required. Get Job Leads Today! . Effect at 10,000 psi; Rough ends before capping: 27: 7300: Reuse of plastic molds: 22: 7800: Use of cardboard molds: 21: 7900: Convex end, capped: 12: 8800 .Intertek-PSI’s technicians are trained and equipped to use a wide range of sampling procedures, destructive and non-destructive testing methods to verify the quality, strength, and durability of construction materials like concrete, asphalt, soils, aggregates, steel, roofing, and masonry.

The latter half of the estimated load must be applied to the specimen at a rate of 0.25 ± 0.05 MPa/s [35 ± 7 psi/s]. . ASTM C192 / AASHTO R 39 - Making and Curing Concrete Test Specimens in the Laboratory. ASTM C470 / AASHTO M 205 - Molds for Forming Concrete Test Cylinders Vertically.

PSI Oklahoma City has a staff of engineers and industry professionals who understand the nuances and unique requirements of state and local building codes and testing standards. The Oklahoma City team has worked on some of the most iconic building and infrastructure projects in Oklahoma such as: Phillips 66-Cushing Station, Kay Wind Farm and .Incorporating the right mix ratio, like the 4000 PSI concrete mix ratio, and ensuring proper installation practices will help in achieving a driveway that stands the test of time and use. Homeowners seeking to maximize their investment should not overlook the importance of regular maintenance, including PSI concrete testing, to safeguard the .

The 28 days concrete test results are accepted as standard compressive strength values. The compressive strength acceptance is specified by 26.12.3.1 of ACI 318-14 as : . (5000 psi), no test results should fall below the specified strength by more than 10%. Also Read: Compressive Strength of Concrete -Cube Test, Procedure, Results. Share This .Concrete compressive strength requirements can vary from 2500 psi (17 MPa) for residential concrete to 4000 psi (28 MPa) and higher in commercial structures. Higher strengths up to and exceeding 10,000 psi (70 MPa) are .

Corrosion testers are used to detect corrosion before the expanding rust exerts pressure inside the concrete, causing it to expand, crack and damage the surrounding concrete. Ultrasonic testing of concrete is an in-situ test to measure the thickness of concrete and tunnel linings, and to determine localized defects such as voids and . After being tested, concrete is given a PSI rating. The ideal PSI concrete rating depends on the concrete's use, but concrete almost always has a PSI rating of 3,000 or more. That's compressive strength. But how is the tensile strength of concrete tested? Testing the Tensile Strength of Concrete

typical compressive strength of concrete

Non-destructive tests of concrete is a method to obtain the compressive strength and other properties of concrete from the existing structures. This test provides immediate results and actual strength and properties of concrete structure. The .The ultimate strength of concrete is influenced by the water-cementitious ratio (w/cm), the design constituents, and the mixing, placement and curing methods employed.All things being equal, concrete with a lower water-cement (cementitious) ratio makes a stronger concrete than that with a higher ratio. [2] The total quantity of cementitious materials (portland cement, slag .Concrete Compression Machines from Gilson meet all ASTM/AASHTO strength testing requirements for conventional concrete test cylinders. A complete selection of compression machine accessories allows easy configuration of all models to test concrete cores, cubes, and flexural beam specimens. . psi (kPa) w/6x12 Cylinder; Automatic Series .The compressive strength of M20 grade concrete varies between 17 and 23 N/mm2 (i.e. between 170 kg/cm^2 and 230 kg/cm^2) after 28 days curing. This means that the concrete can withstand a compressive load of 170 to 230 kg/cm² before it fails.. In compressive strength test of concrete cube the push force applied on the both faces of concrete specimen and the maximum .

Testing methods for measuring concrete PSI strength. Measuring concrete strength is a critical component of quality control and assurance. Various testing methods, such as the compressive strength test, the flexural strength test, and the split-tensile strength test, are used to evaluate the concrete’s performance and ensure that it meets the . Also, 95% of all concrete testing machines in operation are hydraulically actuated and require oil pressures to 68.9 MPa (10,000 psi). The maximum pressure that conventional servo-hydraulic testing systems operate is 31 MPa (4500 psi). Their inability to operate at oil pressures to 68.9 MPa (10,000 psi) and their high cost preclude them from . 3000 PSI Concrete Mix Calculator Enter Total Volume of Concrete (cubic feet): Calculate Mix Here’s a comprehensive table that outlines all you need to know about a 3000 PSI concrete mix. . Testing: Concrete strength can be tested using standard compression tests. Test cylinders are commonly used to determine compressive strength. Common .Equipment for Concrete Strength Testing. To break cylinders, you will need several pieces of equipment. . A good spot is around 11000 lbs for a 6x12 cylinder breaking at 4000 psi. Remember that psi is load divided by the area, so you could calculate this for any size cylinder and any specified strength. Put the machine on hold and check the .

Rebound Hammer test provides a practical and cost-effective solution for estimating in-place concrete strength. Recent developments in rebound hammers, and improved guidelines for estimating concrete strength can help structural engineers and condition assessment professionals in accurately classify concrete strength, and make data-informed decisions on .

qbd 1200 laboratory toc analyzer

qbd1200 laboratory toc analyzer

Resultado da Esqueceu sua senha? 2.24.1.7277 .

testing concrete psi|concrete psi ratings chart